Contribute

| Technology - Rapid Solidification Using Containerless Processing |

David J. Fair and Rakesh Venkatesh

09/17/2005

Every metal object we see around us has specific material properties

such as yield strength, fracture toughness, and electrical

resistivity. Many of these properties are dependent on the

crystalline structure of the metal on a microscopic level. For

example two pieces of identical alloy composition may have vastly

different yield strengths because one of them may have very large

crystal grains, while the other may have very fine crystal

grains. One of them may have been heat-treated or work hardened

leading to substantially better strength or hardness. Thus the

manufacturing processes with which a metal is created is very important

to the life and usefulness of that metal.

Among other

things, the Thermal Analysis of Materials Processing Laboratory (TAMPL)

at Tufts University studies a particular facet of the creation of

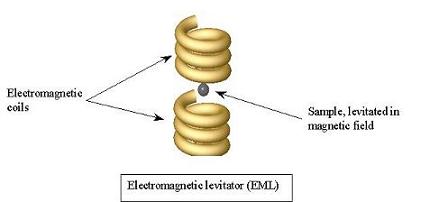

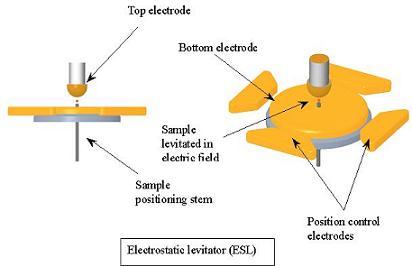

metals, solidification. Using both an electromagnetic levitator

(EML) and an electrostatic levitator (ESL), we are studying the process

of rapid solidification.

Rapid solidification occurs

when a liquid is brought to a temperature below its freezing point

while still a liquid. In this state, the metal is called

“undercooled†or “supercooledâ€. Because this state is very

unstable thermodynamically (the metal really wants to be a solid, not a

liquid), as soon as one tiny piece of solid is formed inside the

liquid, the entire piece of metal solidifies very quickly. This

tiny piece of solid is called a nucleus, and its formation is called

nucleation. A nucleus can form by liquid atoms sticking to either

some surface on its container, or some impurity in the liquid; this is

called heterogeneous nucleation – a nucleation that occurs on something

that is not part of the alloy itself. A nucleus can also form by

liquid atoms sticking to each other, or homogeneous nucleation.

Because it is much easier for heterogeneous nucleation to occur than

homogeneous, we must minimize the possibility of heterogeneous

nucleation in order to reach the undercooled state in our tests.

The biggest place for atoms to stick in a molten metal is the walls of

the container in which it is sitting, so this should be the first thing

we remove. In order to remove the container from the process, we

melt and solidify our samples in either the EML or the ESL, which allow

us to simply suspend the sample in an either a magnetic or electric

field, not touching anything.

We

also use only high purity metals to create our alloys to minimize the

amount of impurities inside the sample. In the lab, we frequently

have undercoolings as great as 150° C. At such undercoolings, the

solid crystals grow through the undercooled liquid at speeds of 3-10

meters per second. Because our samples are small (EML samples are

~7mm, ESL samples are ~2mm), the entire sample solidifies in less than

a millisecond. The only way to view these events is using a very

high-speed camera, 40,000 to 100,000 frames per second.

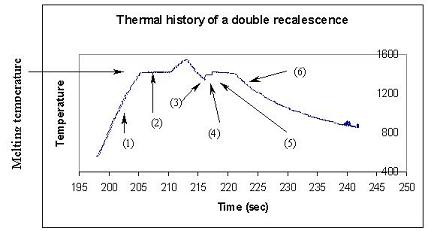

There are certain kinds of alloys which exhibit a phenomenon known as

“double recalescence†when they are undercooled below a certain

Temperature. Because solidification occurs so rapidly in these

scenarios, the energy of the liquid that is lost to the creation of

atomic bonds (latent heat of fusion) is suddenly released into the

sample and the surrounding environment. The result is a sudden

rise in temperature that is visible to the eye as a flash of

light. This is called a recalescence. A double recalescence

is caused by a second phase transformation, from one type of solid to

another type of solid. This means that these alloys actually

solidify twice! First they transform from the liquid phase to a

metastable solid phase, then after a short incubation time, they

transform to a different solid phase, this time a stable solid

phase. The result of this whole process is that the finished

material has a uniform, very small crystal grain structure, which means

that it has favorable material properties. The temperature plot

below shows a typical double recalescence event. The sample heats

up (1), the sample melts (2), the sample undercools (3), the first

recalescence (4), the second recalescence (5), and the sample cools as

a solid (6).

Unfortunately,

there are many factors involved in this event. Because the growth

velocities of the two phase transformations are different functions of

undercooling, there are regimes where the first is faster than the

second and vice-versa. Therefore, in order to have the entire

material experience the double recalescence and to have the favorable

microstructure, a third factor comes into play, the incubation time of

the metastable phase.

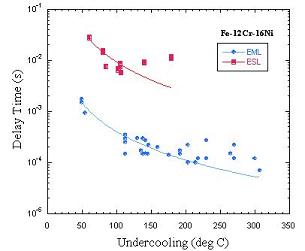

We know that the incubation time

of the metastable phase, commonly referred to as the delay time, is a

strong function of at least the alloy composition and

undercooling. Past research has shown that it is also a function

of something else, and that is the focus of our current research.

When comparing delay time data taken in the EML with that

taken in the ESL, it is clear that there is roughly an order of

magnitude difference between them.

We have considered 3 possible factors so far, based on the differences

in test environments: first, the effect of alloy change due to

preferential evaporation of Chromium from the melt, second, the effect

of difference of sample size between EML and ESL samples, and third,

the presence of magneto-hydrodynamic (MHD) convection in EML and its

absence in ESL. While we have shown that the first two cannot be

the driving factors in the difference in delay times, it is possible

and appears likely that the MHD convection may be an important

factor.

This research is sponsored by NASA grants

NAG8-1685, NNM04AA31G, and the NASA GSRP grant NAGT5-50445. The

ESL facility is located at the NASA Marshall Spaceflight Center in

Huntsville, Alabama; the EML facility is located at Tufts

University.

You may also access this article through our web-site http://www.lokvani.com/

Rakesh Venkatesh

David J. Fair